Sudhir Fasteners houses cold forming capabilities for products ranging from 3mm to 14 mm in cross section. Cold forming is a high speed forging process where coiled wire at room temperature is precisely sheared to length, and then moved through a succession of tool and die cavities to displace the working metal, either larger/smaller in diameter, longer/shorter in length, or to remove small amounts of material by trimming or piercing. Metal is forced beyond its yield (elastic) limit and retains its altered shape upon removal from the die. This technology has evolved over the years and is typically used in the large scale manufacturing of fasteners and certain other engineered products used in automotive, construction and industrial markets.

Advantages of cold formingHeading is a metalworking process which incorporates the forging, extruding and upsetting process.It is often performed in the cold state, under crystallization temperature resulting in cold working. This process typically produces a very precise blank, which means the final product is almost finished in the heading processes although sometimes further processing is required. The cold forming process enables material cost savings up to 70% by avoiding the production of scrap from the machining process, improved product performance due to rearrangement of the grain structure to follow the part configuration. The productivity is also improved on account of higher production speeds thus improving overall cost structure. Also, the cold working processes produces better surface finish and closer tolerances in full scale production with complex and intricate contours and shapes, thus reducing reliance on secondary operations.

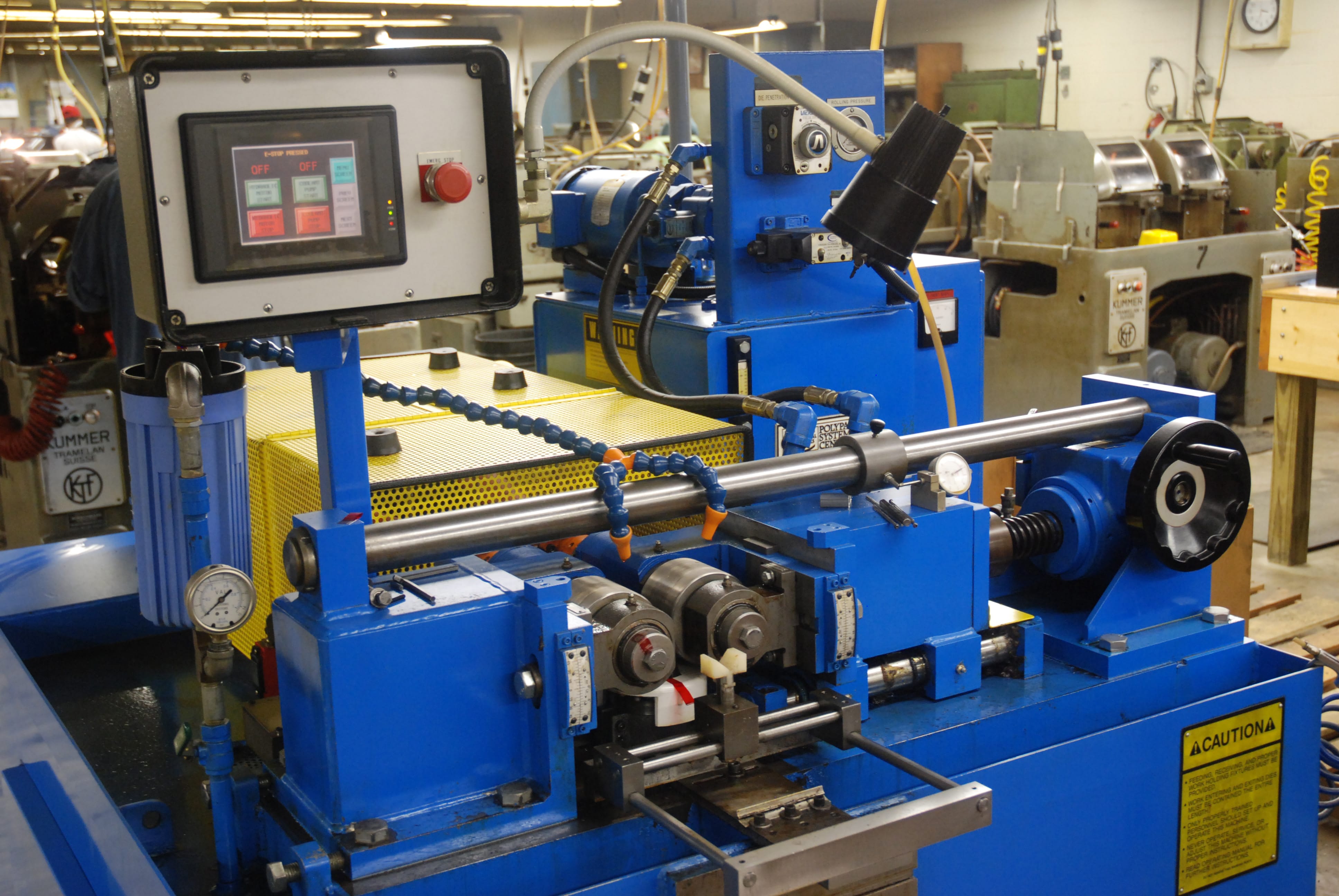

Thread rolling is a highly versatile cold forming process, that can be done on any type of ductile metal to harden, strengthen, or change the material’s physical properties below crystallization temperature of the material. Unlike traditional cutting and grinding methods, no metal is lost or cut away during the thread rolling process; it is simply reshaped. The fastest, most economical method for producing highly accurate threads, thread rolling allows for higher repeatability, stronger threads, and better finish quality and mechanical properties than grinding, cutting, or chasing. Thread rolling improves metal tensile strength by 30% or more compared to traditional cutting methods, and, due to the hardening phenomenon the material undergoes during the rolling process, increases fatigue strength by 50-75%. Sudhir Fasteners manufactures threads conforming to ASTM, JIS, DIN and ISO standards.

High Carbon Fasteners made to comply with grades 8.8/ 9.8/10.9/12.9 require the fastener to be processed through a hardening and tempering process post thread rolling operation. The process is typically conducted in an electric or gas fired furnace with strict temperature zone controls to prevent carburization or decarburization thereby improving the hardness and tensile strength of the fastener. Self tapping fasteners also are processed through a similar heat treatment process but with different temperature zones to case harden the fastener as required by the application. Sudhir Fasteners produces fasteners in all above mentioned grades for a variety of applications leveraging CQI 9 complaint and SCADA enabled furnace set up in house.

Plating process is typically conducted at the end of the fastener value chain to impart rust prevention and aesthetic properties to the fastener. Sudhir Fasteners, leverages its in-house plating plant and process expertise to provide excellent salt spray life and dry film thickness for our customers. We offer in-house Zn alkaline and Zn -Ni alkaline plating service to our customers. Along with these other types of surface finishes available at our works in collaboration with our strictly controlled vendor base are Copper Nickel, Zinc Aluminum Flake coating, Tin plating and Phosphating. For further details on types of surface finish please send your enquiry to [email protected] .

Sudhir Fasteners makes products with secondary operations for our customers as requested. The portfolio of

secondary processes at Sudhir fasteners involves the following:

Sudhir Fasteners strives to minimize it's impact on the environment . This is achieved through responsible disposal of chemical waste from special processes by leveraging the most current technology in treatment of chemical waste and water from plating and heat treatment plants to minimize impact on the environment. 95% of the waste water post purification is used domestically for growing trees in the vicinity of the plant and the remainder is responsibly disposed through services made available to us through local governing bodies. Sudhir Fasteners will continue to strives towards complete re-utilization of the byproducts of our operations as part of our continuous improvement culture.